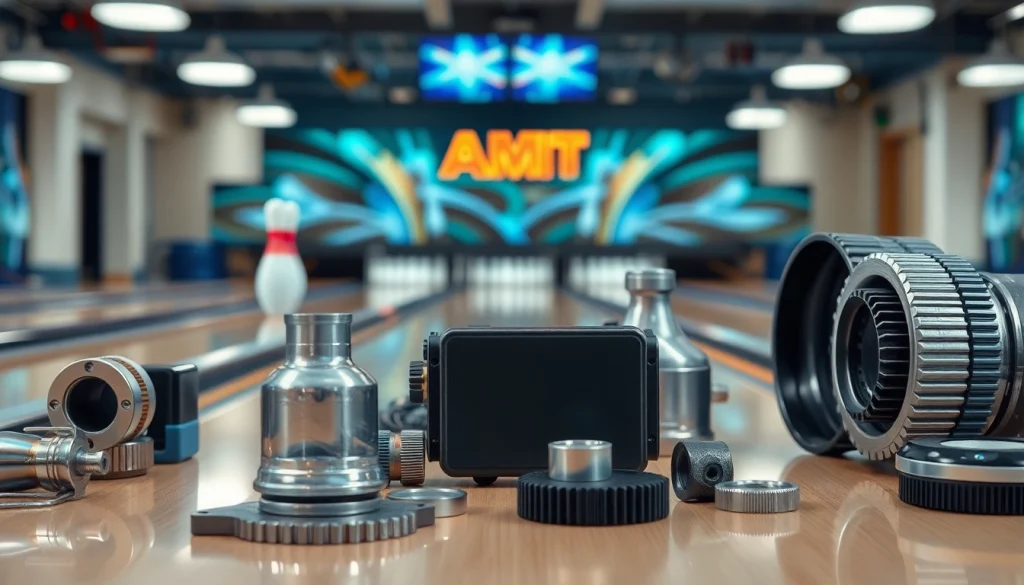

Essential Bowling Parts for AMF: Your Complete Guide for 2025

Understanding AMF Bowling Parts

In the world of bowling, the quality of equipment and its components plays a crucial role in the performance and enjoyment of the game. AMF (American Machine and Foundry) has been a significant player in the bowling industry, providing high-quality machines and parts for centers and individual bowlers alike. Understanding bowling parts for AMF is essential for ensuring that your equipment runs smoothly and lasts longer.

What Are AMF Bowling Parts?

AMF bowling parts consist of a wide array of components specifically designed for AMF bowling equipment, including pinsetters, ball return systems, and scoring machines. These parts are manufactured to exacting standards, ensuring compatibility and optimal performance. With the extensive range of parts available, users can replace worn or broken components to maintain their equipment’s efficiency and reliability.

The Importance of Quality in Bowling Parts for AMF

When it comes to bowling, the quality of replacement parts is paramount. High-quality AMF parts not only ensure smoother operation but also enhance safety by reducing the risk of machinery failure. Poor-quality components can lead to frequent breakdowns, costing bowling centers significant time and money in repairs. Investing in genuine AMF parts guarantees durability and longevity, ultimately benefiting both the center and its customers.

Common Types of Bowling Parts for AMF

- Pinsetter Parts: These include belts, motors, and sensors that are vital for the accurate functioning of the pinsetter.

- Ball Return Components: Parts such as rollers, trays, and motors ensure seamless delivery of the bowling ball back to the player.

- Scoring Systems: This includes electronic components that manage the scoring and lane conditions, significantly enhancing the bowling experience.

- Lane Maintenance Tools: Tools for maintaining the lanes in the best condition, including oiling systems and cleaning machines.

Identifying Genuine AMF Parts

Identifying genuine AMF parts is crucial for ensuring the optimal performance of bowling equipment. With a vast market for bowling parts, counterfeit products can often tempt buyers. Understanding how to spot authentic parts can save money and frustration in the long run.

How to Spot Counterfeit AMF Bowling Parts

Counterfeit parts may seem attractive due to their lower prices, but they often lack the durability and precision of genuine AMF components. Signs of counterfeit parts include lack of proper branding, inconsistent product finishes, and poor packaging. Always purchase from reputable suppliers to ensure authenticity.

Why Choose OEM Parts Over Generic Alternatives?

OEM (Original Equipment Manufacturer) parts are crafted specifically for AMF machines, ensuring a perfect fit and high reliability. Generic alternatives may not meet the same quality standards and can lead to compatibility issues or premature wear and tear. For equipment that relies heavily on precision, such as bowling machines, the difference in quality can be significant.

Certification and Quality Assurance in Bowling Parts

Genuine AMF parts typically come with certifications that attest to their quality and performance. These certifications are essential for maintaining the integrity of your bowling equipment and ensuring you comply with industry standards.

Benefits of Using Advanced AMF Bowling Components

With the technological advancements in the bowling industry, modern AMF parts come equipped with features that significantly enhance performance. Investing in advanced components can lead to improved gameplay, increased customer satisfaction, and reduced maintenance costs.

Enhanced Performance with Modern AMF Parts

Today’s AMF bowling parts utilize cutting-edge technology that allows for finer control of mechanical processes, leading to improved accuracy in pin setting and ball delivery. Enhanced electronic scoring systems provide real-time updates and can integrate with mobile applications, offering bowlers a more interactive experience.

Durability and Reliability in High-Intensity Use

AMF parts are designed to withstand the rigors of high-volume use, making them ideal for busy bowling alleys. The materials used in manufacturing these parts are selected for their durability, ensuring they can handle the wear and tear of daily operations.

Technical Innovations in AMF Bowling Technology

Recent innovations, such as automated lane conditioning and high-speed ball return systems, represent significant strides in bowling technology. These advancements not only improve the overall experience for bowlers but also streamline operations for bowling centers.

Maintenance and Care for AMF Bowling Parts

Proper maintenance is key to extending the lifespan of AMF bowling parts. Following best practices can reduce the frequency of repairs and help maintain the quality of the bowling experience.

Best Practices for Maintaining Bowling Equipment

Regular maintenance routines should include checking for wear and tear on critical components, cleaning electronic systems to prevent dust buildup, and lubricating moving parts. Implementing a scheduled maintenance program can help identify issues before they become major problems.

How to Extend the Lifespan of AMF Parts

Using genuine AMF parts during repairs and replacements is the first step. Additionally, educating staff on the correct operation and care of the equipment can prevent misuse that leads to premature damage.

Signs Your AMF Parts Need Replacement

Common signs include irregular pin setting, unusual noises during operation, and slower-than-normal ball returns. Should any of these issues arise, prompt action should be taken to assess whether a replacement is necessary.

Future Trends in Bowling Parts for AMF

The bowling industry is continuously evolving, and staying ahead of trends can provide competitive advantages. Understanding the future of AMF bowling parts is essential for center owners and operators.

Emerging Technologies in Bowling Parts by 2025

Looking ahead, advancements such as smart bowling lanes equipped with sensors for real-time performance analytics and predictive maintenance systems are on the horizon. These technologies promise to revolutionize the bowling experience and improve operational efficiency.

The Role of Sustainability in Bowling Manufacturing

As the industry moves towards sustainability, manufacturers are exploring eco-friendly materials and processes. AMF may focus on reducing waste and energy consumption in manufacturing, promoting a more environmentally responsible bowling industry.

Expert Insights on the Future of the Bowling Industry

Industry experts predict a focus on enhancing customer experiences through interactive technologies and personalized services. Bowling centers that invest in quality parts and maintain their equipment will likely thrive as the industry evolves.